Quality Control

We build up our original quality control system and make efforts to reduce percent defectives to zero.

We provide high quality, reliable products by imposing standards stricter than the tolerances designated by customers.

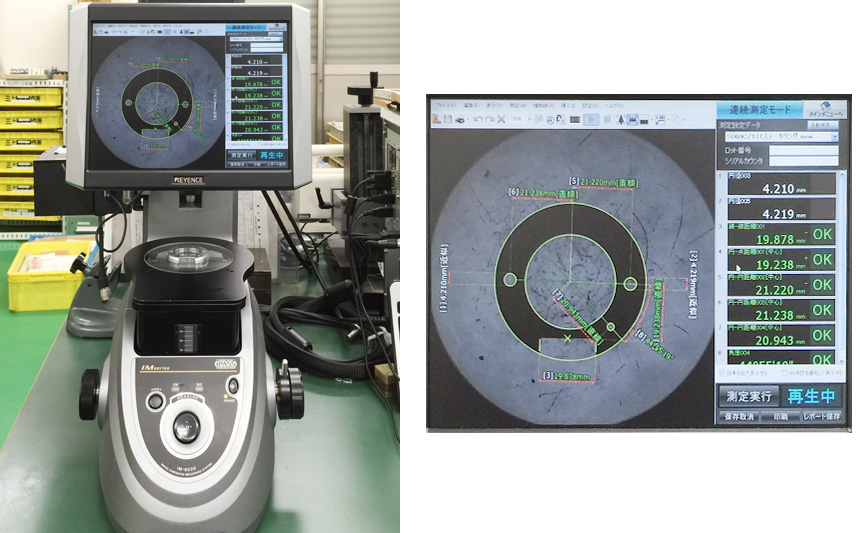

In cooperation with manufacturers, we created a system where the inspection machines operate in conjunction with the processing machines for the product inspection process. Immediately after detecting any deformation or distortion due to heat in the manufacturing process, automatic compensation is made. We can inspect thirty thousand to forty thousand products in one month; therefore, we measure all the products to prevent the outflow of defective products.

We all strive as one in the pursuit of quality.

Inspection Facilities for Quality Control

| Manufacturer Name | Measuring Machine Name | Type |

| Nikon | Profile projector | V-16 |

| Mitutoyo | Profile projector (with image processing system) | PJ-H3000F |

| KEYENCE | Image dimension Measuring System | IM6020 |

| Akashi Seisakusho Co., Ltd. | Micro hardness tester | MVK-D |

| Tokyo Seimitsu | Roundness measuring instrument | RONDCOM41C |

| Tokyo Seimitsu | Surface texture measuring instrument | SURFCOM130A |

| Tokyo Seimitsu | Contour measuring instrument | CONTOURECORD1700DX3 |

| Profile projector | Contour measuring instrument /Surface texture measuring instrument |